Jun 2024 - Aug 2024

Austin, Texas

May 2023 - Jan 2024

Cupertino, California

May 2022 - Aug 2022

Marietta, GA

Over the past four years, I've designed hundreds of parts including CNC-machined and snap-fit injection-molded components as well as simpler 3D printed and lasercut parts.

From using topology optimization to lightweight parts to using structural simulations to narrow down snap fits, I simulate and validate all my components in FEA. I've also developed physical test fixtures and methodologies to validate these simulations in real life.

I've written CAM in HSM and Mastercam for dozens of complex multi-fixture components in materials like titanium and stainless. I also have mass-production experience working with overseas suppliers at Apple.

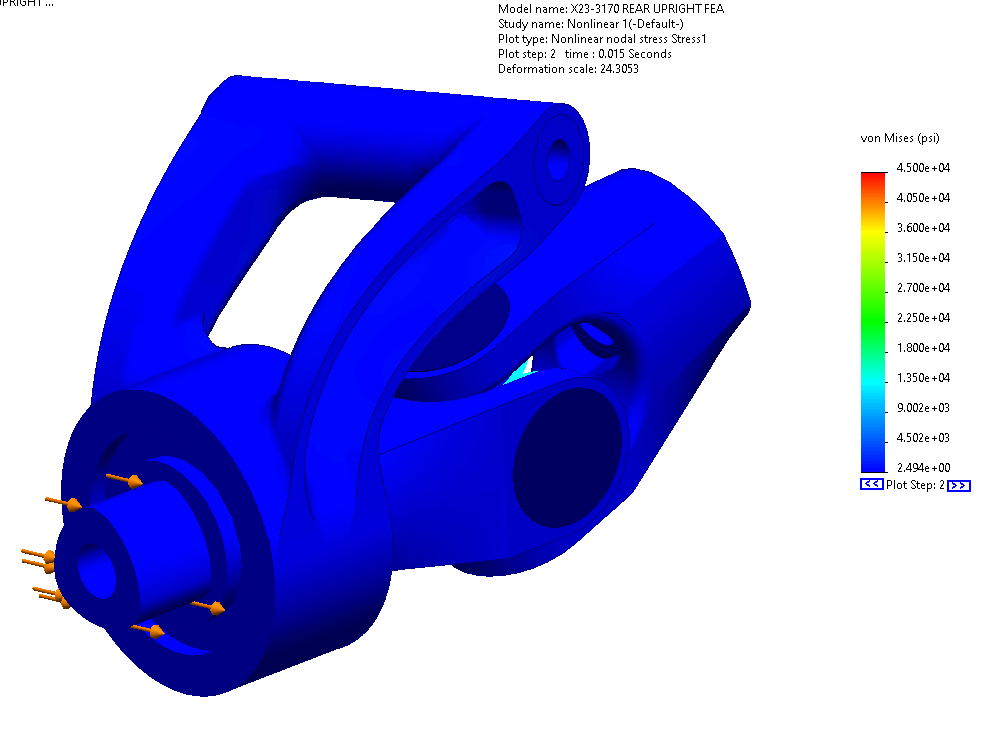

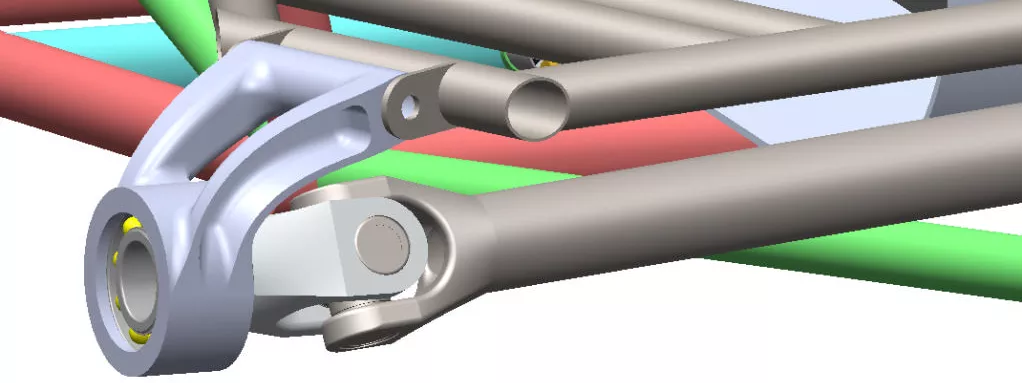

I completely redesigned our teams rear-upright for manufacturability using a first-principles approach. I effectively cut the part's size in half while maintaining all suspension-related requirements, reducing machining time, stock cost, and overall weight.

This part was a 4th axis fixture along with a vise fixture. CAM was written in HSM and machine time was reduced from ~8 hrs to 4.

Nonlinear dynamic simulation of the entire assembly. In order to get more accurate results of various wheel impacts, and properly model the bearing stress on the upright, I ran FEA on the entire assembly instead of the individual part.

The upright integrates with the rest of the rear suspension assembly, and is designed to have zero camber gain over travel.

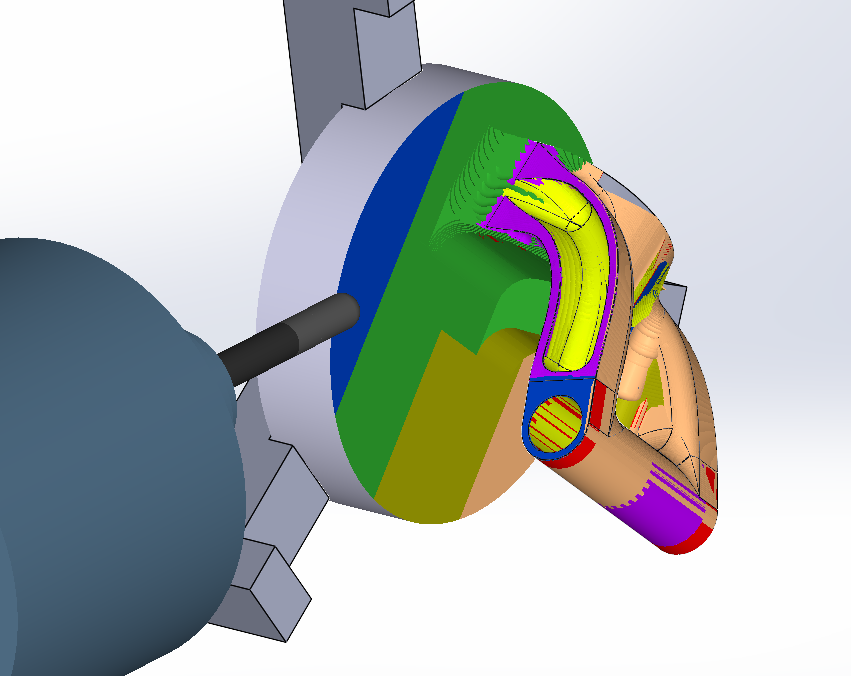

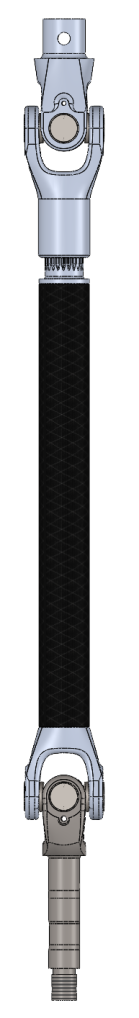

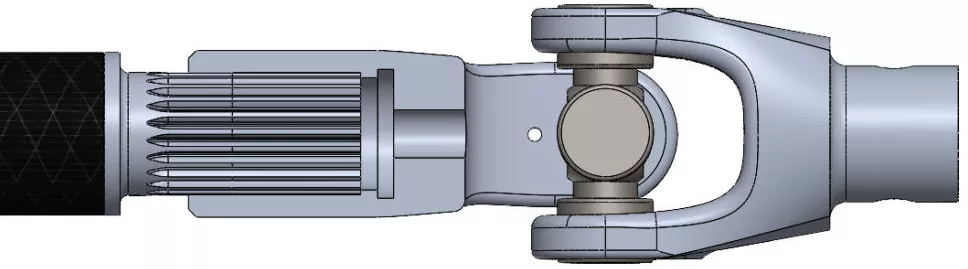

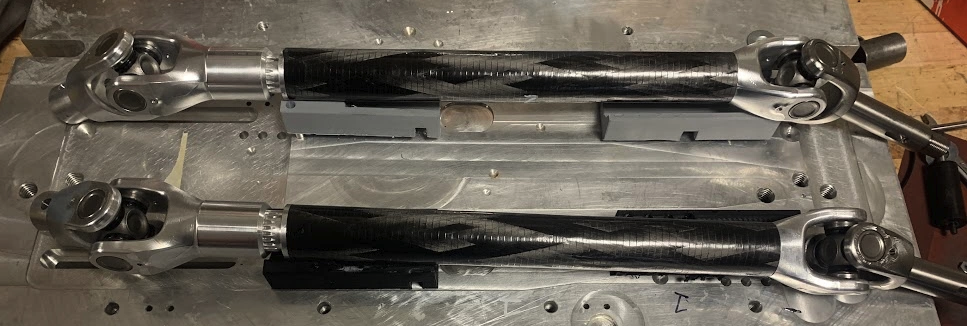

I designed our front half-shaft assembly for the 2022 season as well. It’s validated to take up to 2500 in-lbs with a factor of safety of 1.5 or higher across the board. Using materials like Grade 5 Titanium and 7075-T6, our yokes are able to achieve max angles of 57 degrees. It also uses bonded carbon fiber shafts in order keep the weight of the entire shaft just under a pound.

Because we use a double-wishbone suspension, our shafts have to plunge inwards. We use ANSI B.92 Splines to achieve this while also transferring our torque requirement.

I also designed custom fixturing to bond these half-shafts in an oven to meet our torque transfer requirements.

Aidan Rosenbaum and I built this 2D Pantograph controller with force feedback for our Final Project in ECSE 600 (Design and Control of Haptic Systems). We implemented inverse & forward kinematics, as well as virtual fixturing (in this GIF, it's a horizontal line), as well as position scaling and clutching. [paper] [github]

A self balancing inverted pendulum using a reaction wheel I made for my capstone project. It's able to react to disturbances and recover from 30 degrees from center.

I collaborated with Swedish youtuber Wintergatan my Freshman year. I waterjet the brass escapement gears seen in this video's thumbnail, and gave some advice on DFM.

In my free time I designed and built an E-Bike. Better pictures coming soon.

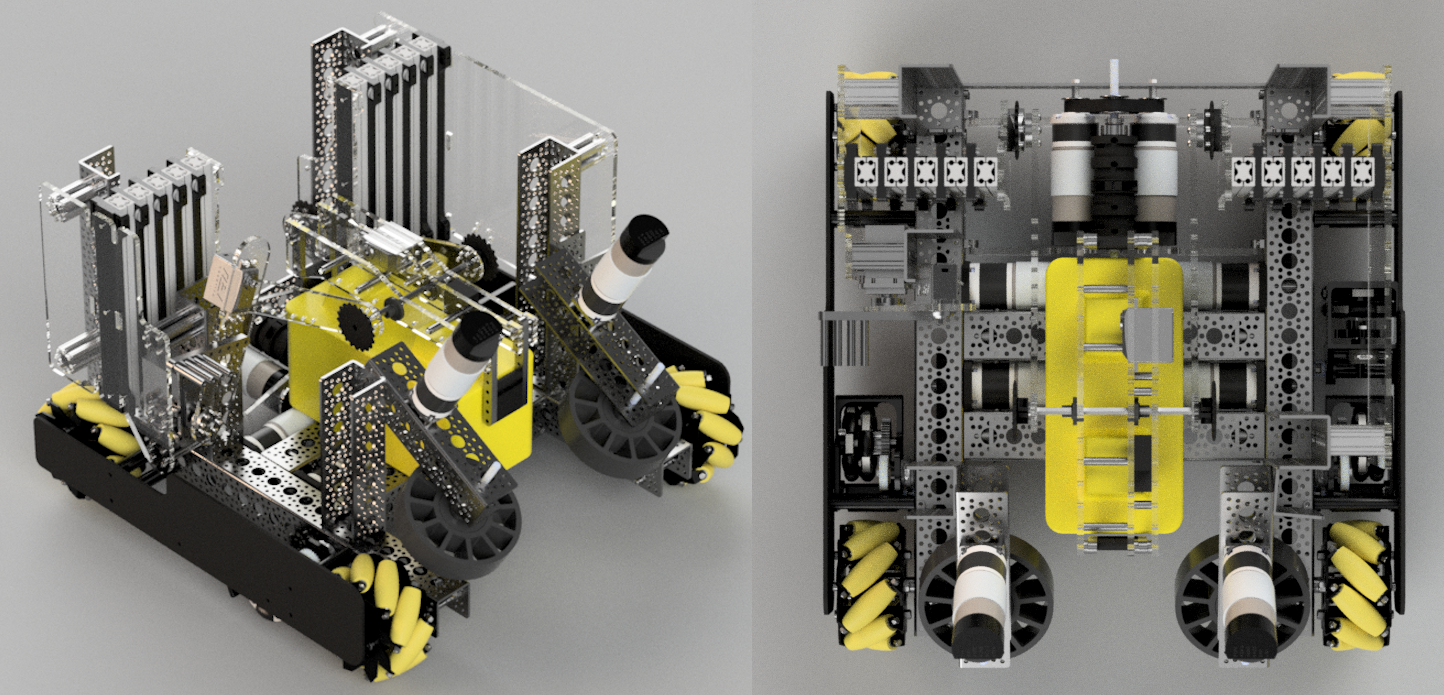

I was the design lead for my high school's FTC team. I designed the robot above, which swept in NJ and got to state finals in Pennsylvania. The season was cut short by COVID.

I was also a build member of VEX team 7405, where we won the VEX World Championship.

A parametric cycloidal gearbox I made in Solidworks. I made this for fun to explore parametric design. Eccentricity, roller radius, pin diameter, and number of rollers can be adjusted. [github]

A tool changer design I made based on a CNC ATC for serial robots.